Environmental sustainability

Delivering on our promise to environmental sustainability within our closed-loop manufacturing system.

Dedicated to a clean earth.

no risk, all reward.

the effects of timbering

Standing at the forefront of our sustainability goal requires the elimination of virgin material from our manufacturing process. With a product traditionally composed of the fiber found within hard and soft wood, this poses significant effects on the ecosystem surrounding trees and their environmental impact regarding habitat loss, soil erosion, water quality, carbon emissions, etc. As a 100% recycled mill system, our process eliminates the need for the destruction of trees, as our flow of material relies solely on products composed of post-consumer and post-industrial recycled fiber. Pioneering this approach since 1989, our thesis has grown in popularity industry wide.

Did you know…

the paper recycling industry saves an average of 24 million trees anually, as each ton of paper recycled has the potential to save 17 trees.

in a nutshell…

overview

Our process operates to set the standard for long term environmental stewardship within the paper manufacturing industry. We create eco-friendly products while minimizing our carbon footprint. We also emphasize this effect in our usage of the “closed loop system”, reducing the need for freshwater within our process in the continuous circulation of “white-water”. Our finished product is created so that it can be recycled back into our system with maximum efficiency. Focusing on resource, process, and impact, we are able to develop disciplines that generate long-term effects on an environment worth saving.

endless possibilities…

product expansion

Since groundbreaking in 1989, our facilities have gotten creative within the range of potential applications. Currently offering five different product segments, our mills are capable of producing a wide variety of products to be used within interior and exterior construction, protective packaging, converting industries, and beyond. This wide range of application potential allows us to support multiple downstream industry segments.

OUR APPROACH

our

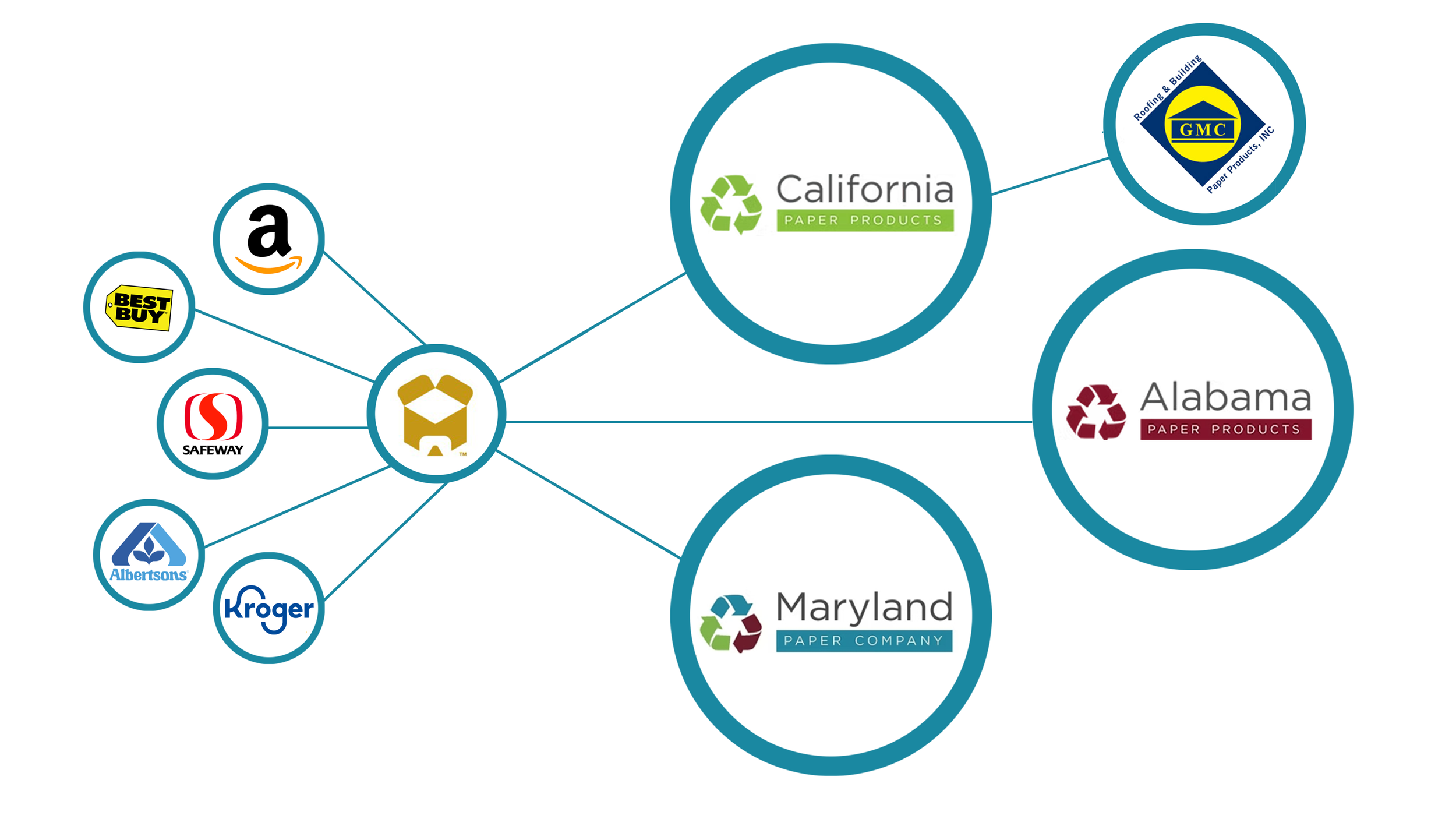

PARTNERS IN

RECYCLING

Our affiliated companies, Golden Bear Recycling and Golden Bear Environmental, exclusively provide our mills with a consistent supply of fiber to be utilized in our plant. Golden Bear is partnered with Kroger, Amazon, Best Buy, Albertsons and more as they create the foundation for our long-term mission.

DO YOUR PART.

LEARN ABOUt RECYCLING OPPORTUNITIES IN YOUR AREA.

Mathew Chakola, Owner and CEO